Rice is one of the most important staple foods in the world, and rice processing is a vital industry in many countries. Rubber roller rice hullers are a key piece of equipment in the rice processing process, and they play a vital role in enhancing efficiency.

How Does a Rubber Roller Rice Huller Work?

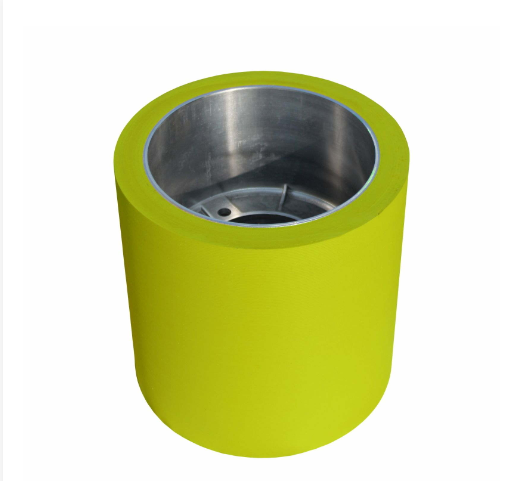

Rubber roller rice hullers work by passing paddy (unhulled rice) between two rotating rubber rollers. The rollers rotate in opposite directions at different speeds, which creates a shearing force that removes the husk from the rice. The husked rice is then separated from the husk and bran using a variety of methods, such as sieving and aspiration.

Advantages of Rubber Roller Rice Hullers

Rubber roller rice hullers have a number of advantages over other types of rice hullers, including:

- High efficiency: Rubber roller rice hullers are very efficient at hulling rice, with husking rates of up to 95%. This is due to the fact that the rubber rollers are able to grip the paddy more effectively than other types of hullers, such as abrasive hullers.

- Low breakage: Rubber roller rice hullers produce less broken rice than other types of hullers. This is because the rubber rollers are less likely to damage the rice kernels.

- Easy maintenance: Rubber roller rice hullers are relatively easy to maintain and operate. The rubber rollers can be easily replaced when they become worn out.

Enhancing Rice Processing Efficiency with Rubber Roller Rice Hullers

There are a number of ways to enhance rice processing efficiency with rubber roller rice hullers, including:

- Using the right rubber rollers: The type of rubber rollers used in a rice huller can have a significant impact on efficiency. It is important to select rubber rollers that are made from a durable material that is resistant to wear and tear. Rubber rollers should also be the correct size and hardness for the specific type of rice being hulled.

- Properly adjusting the rubber rollers: The rubber rollers should be properly adjusted to ensure that they are operating at the correct speed and clearance. The clearance between the rollers should be adjusted based on the size and moisture content of the rice being hulled.

- Using a good quality paddy cleaner: A good quality paddy cleaner can help to remove impurities from the paddy, such as stones, twigs, and straw. This can help to improve the efficiency of the rice hulling process.

- Regularly maintaining the rice huller: It is important to regularly maintain the rice huller to keep it in good condition and operating efficiently. This includes cleaning the machine, lubricating the moving parts, and checking for any signs of wear and tear.

By following these tips, you can enhance rice processing efficiency with rubber roller rice hullers and produce high-quality rice for your customers.