Notifications

ALL BUSINESS

COMIDA

DIRECTORIES

ENTERTAINMENT

FINER THINGS

HEALTH

MARKETPLACE

MEMBER's ONLY

MONEY MATTER$

MOTIVATIONAL

NEWS & WEATHER

TECHNOLOGIA

TV NETWORKS

VIDEOS

VOTE USA 2026/2028

INVESTOR RELATIONS

DEV FOR 2025 / 2026

ALL BUSINESS

COMIDA

DIRECTORIES

ENTERTAINMENT

FINER THINGS

HEALTH

MARKETPLACE

MEMBER's ONLY

MONEY MATTER$

MOTIVATIONAL

NEWS & WEATHER

TECHNOLOGIA

TV NETWORKS

VIDEOS

VOTE USA 2026/2028

INVESTOR RELATIONS

DEV FOR 2025 / 2026

About Me

Asteam Techno Solutions Pvt Ltd

Asteam Techno Solutions Pvt Ltd We are the solution provider stockiest & exporter of Automation products such as PLC, I/O Modules, Drives, HMI, Sensor from reputed brands like Allen Bradley, Siemens, Schneider, AVEVA (Wonderware), etc..

Asteam Techno Solutions Pvt Ltd -

December 20, 2023 -

Technology -

Rockwell Automation Micro800 Controller

Rockwell Automation Micro800 Controller in India

Allen Bradley Micro800 Controller in best price

How to set up and configure the Micro800 Controller

-

308 views -

0 Comments -

0 Likes -

0 Reviews

Asteam Techno Solutions Pvt Ltd -

December 20, 2023 -

Technology -

Rockwell Automation Micro800 Controller

Rockwell Automation Micro800 Controller in India

Allen Bradley Micro800 Controller in best price

How to set up and configure the Micro800 Controller

-

308 views -

0 Comments -

0 Likes -

0 Reviews

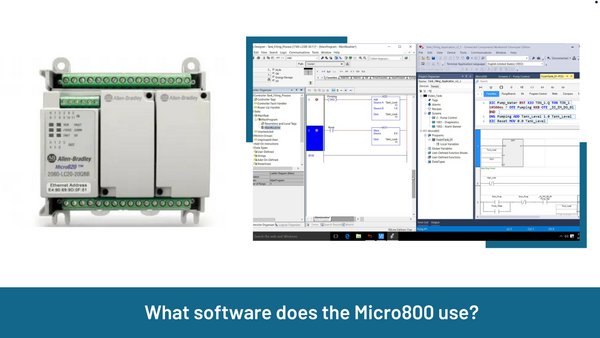

Connected Components Workbench (CCW) software is required in order to program Rockwell Automation Micro800 controllers. A software suite called Connected Components Workbench was created by Rockwell Automation especially for Micro800 controller development and configuration. It offers tools and a graphical programming environment for creating function block diagrams, ladder logic, and structured text programs for Micro800 controllers.

Key features of Connected Components Workbench include:

Programming Environment:

CCW provides an easy-to-use interface for creating programs in a variety of programming languages for Micro800 controllers.

Configuration Tools:

Micro800 controllers, input/output modules, and other hardware parts can be configured and set up using CCW.

Check :- Allen Bradley 2080-LC50-48QWB Micro820 PLC Systems

Online Editing and Debugging

The software offers debugging tools to examine and optimize your control logic, and it lets you make modifications to your application online.

Simulation:

CCW includes simulation capabilities that enable you to test and debug your program without the need for physical hardware.

Firmware Updates

You can use CCW to update the firmware of Micro800 controllers when necessary.

The company that makes the Micro800 series, Rockwell Automation, usually provides specialized software tools needed for programming Micro800 controllers. Micro800 controllers are mostly programmed using Connected Components Workbench (CCW). An integrated development environment (IDE) called Connected Components Workbench provides a simple-to-use interface for setting up, programming, and debugging Micro800 controllers.

When you need to scheduling regular maintenance for the the Rockwell Automation Micro800 controllers, Asteam Techno Solutions Pvt Ltd is here to help you. With an inventory of obsolete and surplus spare parts and a team of qualified engineers, there’s no breakdown or fault we cannot solve. Wherever you are in the world, Asteam Techno Solutions Pvt Ltd is the best Industrial Automation parts supplier and solutions provider in India as well as globally. Get support for all types of equipment from AC, DC and servo drives through to PLCs, HMIs and other automation parts.