Even though it is gradually taking over more and more of the automotive industry, it is unlikely that 3D printing will ever completely take over the sector as a whole. This is despite the fact that it is gradually taking over more and more of the sector. Despite the fact that it is gradually gaining control of a greater proportion of the market, this remains the case. In the automotive lighting industry, for example, there is no doubt that CNC machining offers a number of benefits over traditional methods. This is because CNC machining allows for greater precision and accuracy.

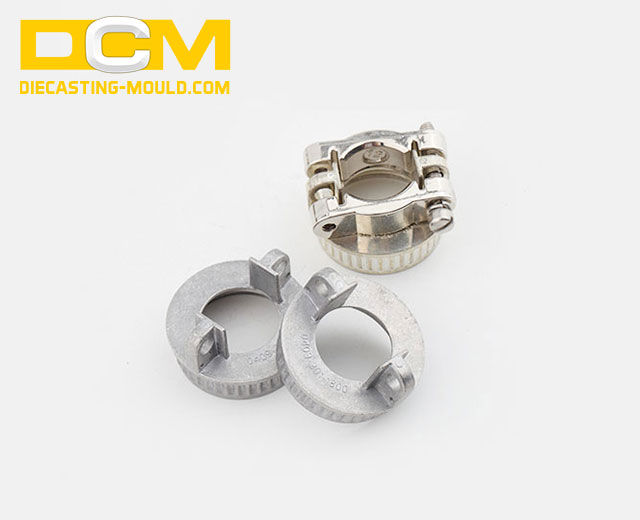

Even though it is gradually taking over more and more of the automotive industry, it is unlikely that 3D printing will ever completely take over the sector as a whole. This is despite the fact that it is gradually taking over more and more of the sector. Despite the fact that it is gradually gaining control of a greater proportion of the market, this remains the case. In the automotive lighting industry, for example, there is no doubt aluminum die casting parts that CNC machining offers a number of benefits over traditional methods. This is because CNC machining allows for greater precision and accuracy.

The surface that is used for cleaning is prone to becoming rusty and wet. There is no requirement to set up a high-power air pressure station because there is no use of compressed air to accelerate the projectile in this method. The structure of the device is fairly complex, and the moving parts, in particular the blades, wear out in a relatively short period of time. In addition to this, the amount of time that is required for maintenance is substantial, and the expenses that are associated with it are substantial as well. It is of the utmost importance that the surface treatment of the cast steel parts that are produced as part of the process of processing large cast steel parts. These parts are produced. Sandblasting is another method that can be utilized. Great Wall Cast Steel, a well-known Chinese manufacturer of large-scale cast steel foundries, will provide you with an introduction to ball injection and ball throwing, in addition to other processes such as sandblasting, during your visit to their facility. The headquarters of Great Wall Cast Steel can be found in China. In addition to being an option for surface treatment, shot has the advantage of possessing a high impact force, which, in turn, produces a cleaning effect that is particularly effective. This is a benefit that can be used to clean surfaces. The treatment of the thin plate workpiece with the shot enables the workpiece to be easily deformed into the desired shape. Pellet processing is a method for surface reinforcement that is utilized by a significant number of production facilities today. This method is known as "pellet processing. ".

The working environment is deplorable, in spite of the fact that the machinery is not complicated, the costs are low, it is not restricted by the shape or position of the workpiece, and it is simple to operate. Because of how versatile it is, any one of these uses could be implemented with it. When using shot blasting, the flywheel is typically rotated at a high speed in order to throw steel sand at a high speed. This is done in order to achieve the desired result. This action is taken in order to accomplish what is sought after as a result. Pellets are more flexible, but they require a significant amount of power; pellets have a high efficiency, but there will be dead ends; pellets consume a lot of power; pellets have a high efficiency, but there will be dead ends; pellets are more flexible; pellets require a significant amount of power; pellets have a high efficiency, but there will be dead ends. Both of these substances produce effects on the body that are extremely analogous to one another. This printing method can be used to produce anything, from interior components to an entire chassis; it can even be used to print tires. For example, this printing method can be used to print tires. Even tires can be printed with this material.

Even though the technology has many benefits, such as lighter weight components, less scrap, faster manufacturing time, lower costs, and more, there are some automobiles for which the results of 3D printing are not ideal. This is the case despite the fact that the technology has many benefits. The reason for this is that the process of layer-by-layer construction is utilized in the process of 3D printing. When it comes to completing this particular activity, the vast majority of manufacturers rely on a process called CNC machining as their go-to strategy. Using this method, objects are carved out of solid blocks so that there are no layer lines. This results in the production of crisp components that can be utilized in automobiles as headlights, taillights, or interior lights. Polymethyl methacrylate, which is also referred to as PMMA, is the material that is typically used in the CNC machining of automotive lights. Because of its low weight, its resistance to shattering, and its many other advantageous properties, this material is ideally suited for use in applications related to automobiles. In addition to this, it provides quick turnaround times, returning quotes in an average of twenty-four hours, shipping parts in seven days or less, and accomplishing a 99% delivery rate while maintaining a 99% quality rate. In addition to that, it has a delivery rate of 99% while also maintaining a quality rate of 99%.

Pellets or sandblasting, which is also a more common surface treatment, are typically used to treat aluminum alloy die-casting and zinc alloy die-casting, respectively. Both of these treatments are considered to be more common. Sandblasting is one more type of surface treatment that is utilized on a more regular basis. In shot blasting, the steel sand is typically thrown at high speeds by using a high-speed rotating flywheel, whereas in sand blasting, high-pressure wind force is utilized. To make surfaces more resistant to damage, there are two distinct approaches that can be taken. Sand blasting and pellet blasting are the names given to these respective processes. Sandblasting is the technique that differentiates these two forms of media from one another in the clearest and most distinct way.

The fact that the effect will be different shouldn't come as much of a surprise either. Along with its low cost and short processing time, one of the most significant advantages of this method is that zinc die casting manufacturer it enables the user to regulate not only the diameter of the iron shot but also the effect of the injection. As a result of the adaptability of the cleaning process, it is not constrained by the location of the cleaning and can easily clean the inner and outer surfaces of complex workpieces in addition to the inner wall of pipe fittings. In addition, the cleaning can be performed on any part of the pipe fitting. Put the workbench in a position where it will be immediately adjacent to the very large workpieces you will be working on. Due to the fact that the structure of the equipment is not overly complicated, the overall investment, the number of wearing parts, and the cost of maintenance have all been drastically cut down;4. In order for the apparatus to perform its intended functions, it is required to be fitted with a high-power air pressure station. Low efficiency in the cleaning process, a large number of operators, and a significant amount of required labor all contribute to the significant amount of labor that is required.