Notifications

ALL BUSINESS

COMIDA

DIRECTORIES

ENTERTAINMENT

FINER THINGS

HEALTH

MARKETPLACE

MEMBER's ONLY

MONEY MATTER$

MOTIVATIONAL

NEWS & WEATHER

TECHNOLOGIA

TV NETWORKS

VIDEOS

VOTE USA 2026/2028

INVESTOR RELATIONS

DEV FOR 2025 / 2026

ALL BUSINESS

COMIDA

DIRECTORIES

ENTERTAINMENT

FINER THINGS

HEALTH

MARKETPLACE

MEMBER's ONLY

MONEY MATTER$

MOTIVATIONAL

NEWS & WEATHER

TECHNOLOGIA

TV NETWORKS

VIDEOS

VOTE USA 2026/2028

INVESTOR RELATIONS

DEV FOR 2025 / 2026

About Me

Shreon Jack

Shreon Jack Passionate blogger with a keen interest in exploring diverse niches, from business trends to the latest in technology. I enjoy breaking down complex topics into engaging, easy-to-understand content that informs and inspires readers across various industries.

Shreon Jack -

8 hours ago -

Business -

material handling conveyors

accumulation conveyors

material handling equipment conveyors

transfer conveyor

-

26 views -

0 Comments -

0 Likes -

0 Reviews

Shreon Jack -

8 hours ago -

Business -

material handling conveyors

accumulation conveyors

material handling equipment conveyors

transfer conveyor

-

26 views -

0 Comments -

0 Likes -

0 Reviews

Selecting the right material handling conveyors is essential for smooth operations and maintaining product integrity. When aligned with specific facility needs, these systems help streamline workflows, reduce product damage, and improve overall productivity.

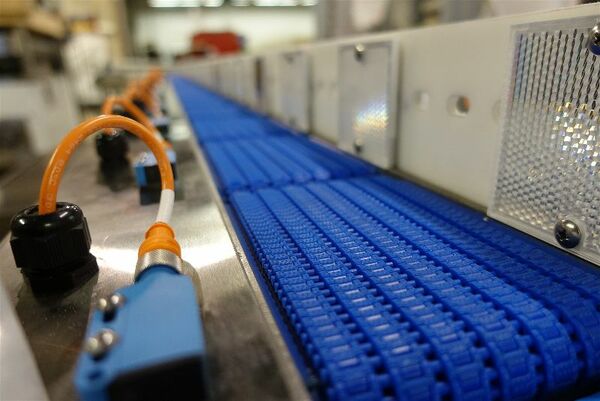

From accumulation conveyors to advanced belt systems, today’s material handling equipment conveyors are built to meet a range of industrial applications. Whether managing fragile goods or optimizing product flow, the right conveyor solution supports consistent output and operational reliability.

This blog examines the role of material handling conveyors in modern facilities and how different conveyor surfaces impact product handling and quality.

Material handling conveyors are the backbone of modern operations. They streamline workflows and improve product handling, increasing efficiency and reducing downtime. As technology advances, so do these systems.

Different types of conveyors bring unique benefits:

● Roller Conveyors: Ideal for heavy loads, offering a sturdy design and smooth product flow.

● Modular Conveyors: Flexible and easily adaptable to growing businesses.

● Automated Conveyors: Reduce labor costs and minimize errors.

In industrial automation, material handling equipment conveyors play a strategic role by moving goods efficiently. One crucial yet often overlooked aspect of these systems? Belt texture.

The right belt surface dramatically impacts product stability, reduces slippage risks, and prevents transportation damage.

Different belt textures address specific handling requirements:

● Smooth belts work wonders with lightweight packages

● Rough-textured surfaces provide extra grip for heavier loads

● Specialty belts with high-friction coatings enhance product control, cutting down on mishandling incidents

Choosing the right material-handling conveyor means understanding how different belt textures interact with specific materials.

Some materials require specialized handling considerations. The texture chosen ultimately impacts efficiency and product integrity throughout the handling process. Companies often underestimate how much their conveyor belt surface affects their bottom line.

Specialized accumulation conveyors hold or buffer products before sending them to the next production or packaging stage. These systems are particularly valuable for fragile items because they eliminate those abrupt movements that often cause damage.

Accumulation conveyors effectively regulate product flow, reducing pressure between items moving along the line. This controlled movement is critical for industries handling delicate materials such as glassware, electronic components, pharmaceutical products, and similar items.

By incorporating accumulation conveyors, businesses ensure smooth material movement while dramatically cutting breakage risks and product wear.

Selecting the right material-handling equipment conveyors is critical when dealing with fragile materials. Some top options include:

● Modular Belt Conveyors: These offer excellent flexibility and handle irregularly shaped items beautifully.

● Roller Conveyors with Low-Pressure Accumulation: These are engineered to move products gently without excessive force

● Kwik-Wash Conveyors: These are designed to meet stringent hygiene standards in industries like food processing and pharmaceuticals.

The right conveyor system ensures that materials are moved with care while improving the efficiency of operations.

Different industries have unique needs when it comes to conveyor surfaces. Here are some sector-specific considerations:

Food-grade operations demand conveyor surfaces that are easy to clean, resist bacterial growth, and comply with strict regulatory standards. They typically feature:

● Non-porous surfaces that prevent food particles from becoming trapped

● Materials approved by the FDA, USDA, and other regulatory bodies

● Quick-release mechanisms for thorough cleaning and sanitization

● Temperature resistance for both hot and cold food processing environments

When handling medications and medical devices, contamination concerns reach another level entirely. Pharmaceutical conveyor systems often incorporate:

● Smooth, easy-to-sterilize surfaces

● Antistatic properties to prevent contamination from dust attraction

● Cleanroom-compatible materials

● Regulatory compliance documentation for validation

Electronics manufacturers face unique challenges with static electricity and component fragility. Their material handling conveyors typically feature:

● Static-dissipative surfaces that prevent ESD damage

● Extremely gentle handling mechanisms

● Precision positioning capabilities for automated assembly

● Clean surfaces that won't generate particulates

Although these specialized conveyor surfaces might cost more initially, they deliver tremendous value through extended service life and reduced maintenance requirements.

Well-integrated conveyors are essential for smooth product movement in material handling. The right transfer conveyor ensures smooth transitions between systems, reducing the risk of misalignment and damage.

Material handling has become essential in modern industries, finding its place in virtually all manufacturing and production sectors. These material handling conveyors enable the smooth transportation of materials, products, and goods across various production, storage, and distribution stages.

What makes the difference between an adequate conveyor system and an exceptional one? Often, it comes down to thoughtful design that considers specific products, production environment, and long-term operational goals.

CONOVEY helps you select the ideal transfer conveyor to maintain product integrity and ensure seamless production flow. Contact us today to find the right fit for your operations!